Previous Projects

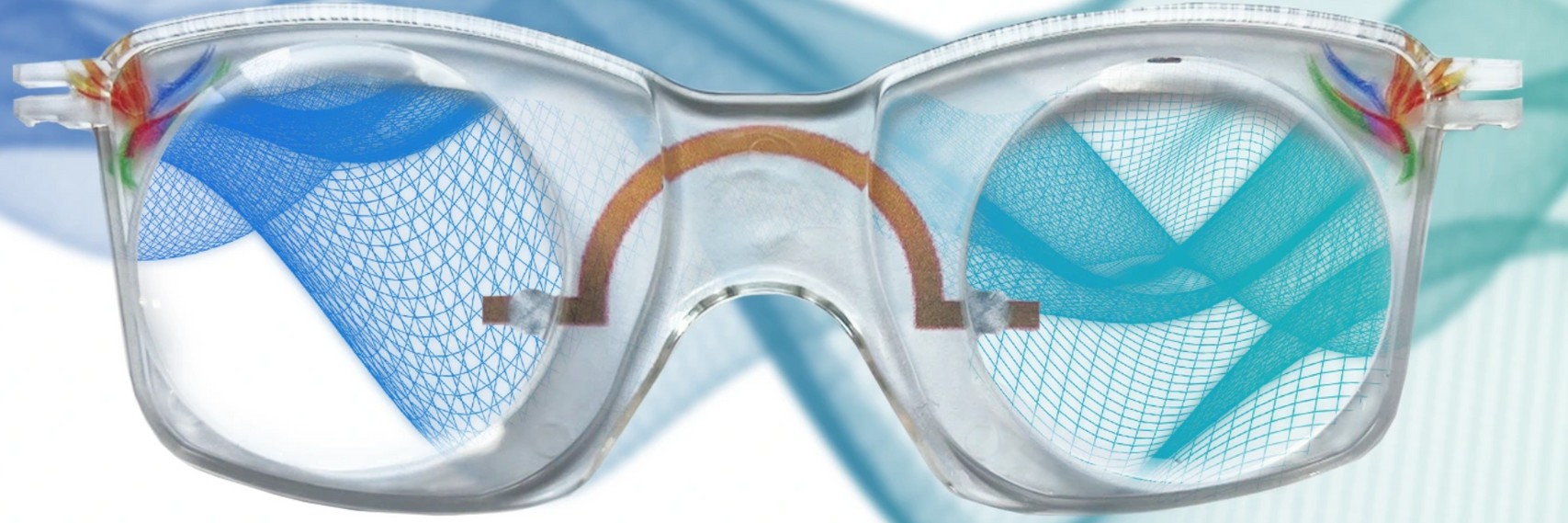

Optician in a Box - Revolutionizing Eyewear Access

An estimated 1.6 billion people worldwide are unable to work due to the inability to afford spectacles. Kent Precision was tasked with designing a cost-effective, adjustable eyewear solution that could be easily customized to the individual user, particularly in developing countries where access to eyewear is limited.

Design and Innovation

The challenge was to create spectacles that could be adjusted in seconds to fit the user's facial features. The solution involved designing adjustable arms that provide up to 80mm of movement, multiple bridge sizes, and various frame widths. This enables the glasses to be quickly dispensed (within 10 minutes) and adapted to suit a wide range of users.

Collaboration and Prototyping

In collaboration with Style Eyes, Kent Precision utilized 3D printing to create initial prototypes. We gathered data on facial features to ensure the design would work universally across different individuals. SolidWorks was used to create detailed drawings and visualizations, with graphics added to the components to simulate the final product.

Tool Making, Design, and Consultation

Through tool making design and consultation, Kent Precision provided expert advice and support at every stage. We then created a prototype tool that allowed us to produce several units for BSI testing, which was essential for achieving certification as a Class 1 medical device. During this phase, we also suggested the addition of a UV stabilizer and a blue additive to ensure compliance with BSI standards and improve the durability of the product.

In-House Production Tooling

Once the prototype passed testing, production tooling was manufactured in-house by our expert toolmakers to support large-scale orders. This ensured that we could meet future demand while maintaining the quality and precision required for the medical device certification.

Future Developments and Features

As the project progresses, future developments include:

- Printed frames for further customization

- Laser-engraved markings on the frames and arms for identification and branding

- 3D-printed future concepts to explore new designs and features