Injection Moulding

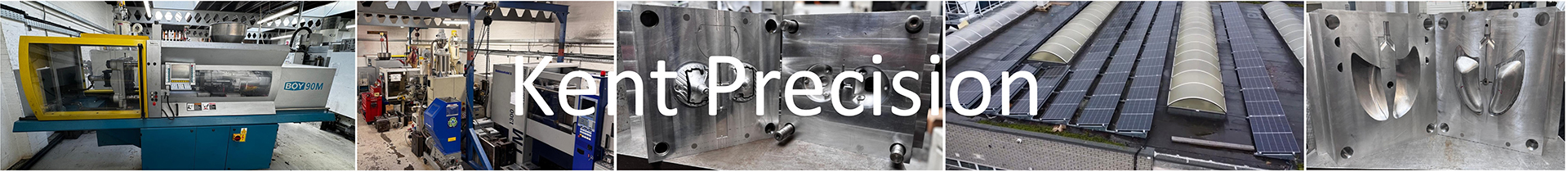

Injection Moulding at Kent Precision

Celebrating over 30 years of excellence, Kent Precision has been at the forefront of delivering high-quality injection moulding services across various sectors. Our ISO9001 certification underscores our commitment to producing superior moulded components while offering additional services such as laser engraving and assembly.

Sustainability Commitment

As part of our dedication to sustainability, we are working toward becoming a net carbon-zero manufacturing facility. In 2023, we installed solar panels, and since then, we have generated 29,621 kWh of energy, helping us reduce our carbon emissions by 29.5 tons. This is just one of the steps we are taking to ensure our manufacturing processes have a minimal environmental impact.

Our Moulding Capabilities

At Kent Precision, we operate a wide range of machines, from 55 to 160 tons, with shot weights of up to 350 grams. This flexibility allows us to handle a variety of injection moulding projects, ensuring we meet the specific needs of each customer.

Outsourcing Larger Tooling Needs

For projects requiring larger tools, we have the ability to outsource tooling to our trusted partners, ensuring that we can accommodate all your needs. This expands our capabilities to manage more extensive or specialized projects while maintaining our high-quality standards.

Lifetime Warranty on Tooling

We stand behind the quality of our work. All tooling created with Kent Precision comes with a lifetime warranty. For more details on what is covered, please visit our guarantee page.

Material Selection and Expertise

We have the capability to mould a broad range of plastics, responsibly sourced from around the world. Our team will work closely with you to determine the best material for your specific application, ensuring optimal performance and cost-efficiency

Polymers we are able to manufacture:

|

|

|

Industries that we currently provide to: