Injection Mould Tooling

Kent Precision: Prototype, short run and production tooling

At Kent Precision, we offer a full range of in-house prototype, aluminium, and production injection mould tooling services, all manufactured at our state-of-the-art site in Erith, London. With over 30 years of experience in the industry, we are committed to providing the highest quality tooling solutions tailored to your specific project requirements.

Tooling Options to Suit Your Needs

We understand that every project is unique. Based on your application, material, and production quantity, we will advise you on the most suitable tooling solution for your needs. Whether you require prototype tooling, aluminium tooling, or steel production tooling, we provide a variety of options that ensure efficiency and durability.

Lifetime Guarantee

What sets Kent Precision apart is our lifetime guarantee on aluminium and steel tooling. This comprehensive warranty covers all tooling for repairs or refurbishment throughout the duration of the project at no additional cost to the customer. Unlike other tooling guarantees, which typically cover only the metal for a limited shot cycle, our coverage ensures that you won't face unexpected repair bills for any remedial or refurbishment work as long as the tool is kept with Kent Precision.

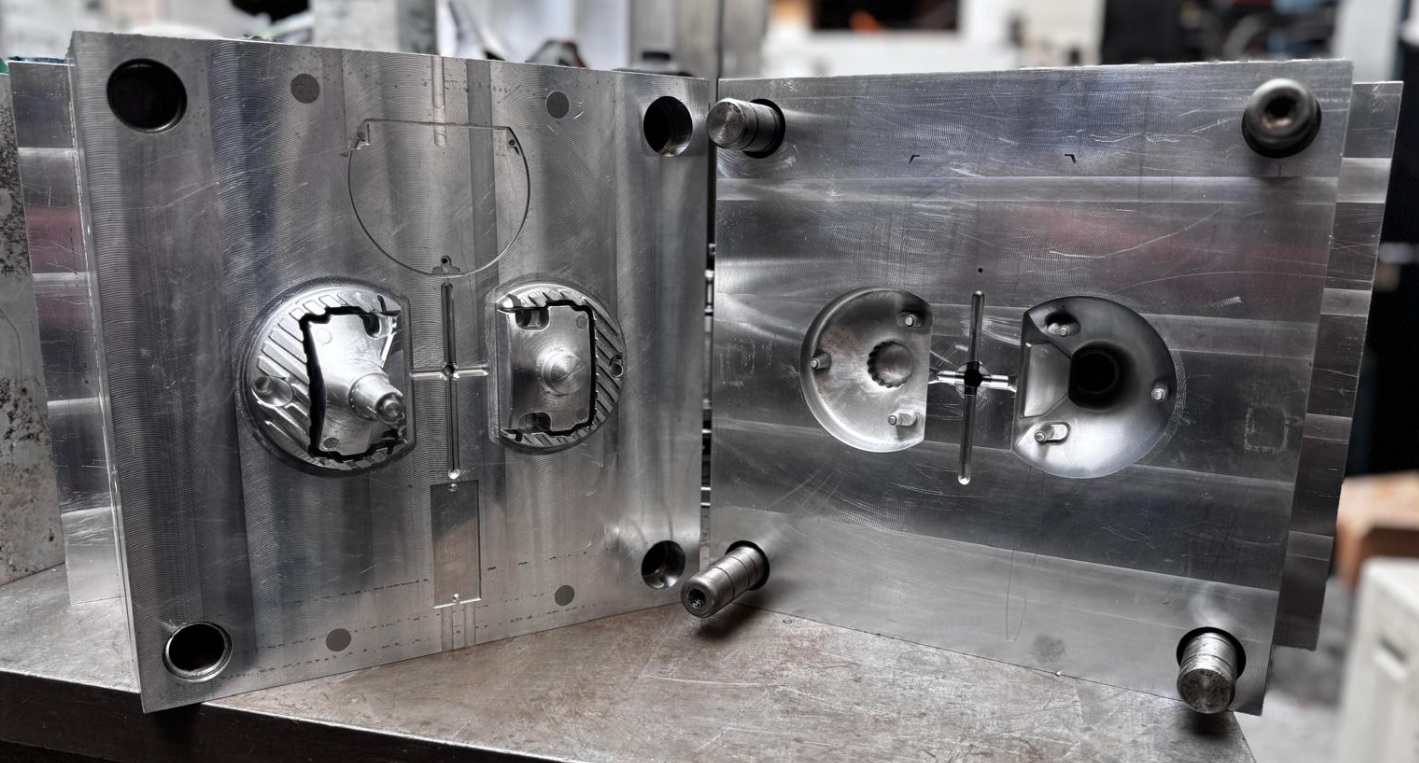

In-House Tooling

All of our injection mould tools are produced in-house to the highest standards , using materials sourced from our approved suppliers. We provide free design and consultation with every tooling order, ensuring that your design is optimized for performance, efficiency, and cost-effectiveness. Additionally, every tool is sampled free of charge, with samples provided for your approval before proceeding with production.

Existing Tooling Relocation & Modifications

Do you have existing tooling that you are looking to relocate? At Kent Precision, we offer tool relocation services and will carry out a detailed assessment of your tooling's condition. If the tooling is suitable, we may even offer a lifetime guarantee on the relocated tool once it is moulded by Kent Precision.

We also offer modifications to existing tooling, helping you extend the life and performance of your current tools.

Comprehensive Tooling Services

Our tooling services include:

Prototype Tooling:

Insert Injection Moulding:Inserts machined with your component's core and cavity are placed within a generic bolster for cost-effective prototype tooling. You own the inserts but not the bolster.

Dedicated Injection Mould: A bespoke bolster made from aluminium with your core and cavity, fully owned by the customer.

Steel Insert Prototype Tooling: Ideal for abrasive materials, such as glass-filled plastics, that could damage the tooling surface.

Aluminium Tooling:

With over 30 years of experience, we offer high-performance aluminium tooling. All our aluminium moulds are backed by a lifetime guarantee, making them suitable for production runs that can last millions of shots. Hardened steel is used in high-wear areas to increase the service life.

Production Tooling:

We specialize in multi-impression, fully hardened steel tooling with hot tip manifold systems for high-volume projects. These tools also come with a lifetime guarantee if moulded at Kent Precision. Additionally, we provide tools for external moulders and support the first run at your facility with on-site assistance from our toolmakers.

Additional Services & Expertise

Material and Additive Selection: We assist with selecting the ideal materials for your project, including PC, ASA, PP, POM, and PA, as well as colour options like pigment dry blends, liquid colour, masterbatches, and more. We also offer additives like antimicrobial, RF shielding, and Verimaster

Mould Flow Analysis: To ensure optimal performance, we provide mould flow analysis to predict the weight, cycle time, and flow of your components.

Why Choose Kent Precision?

Expertise in Injection Mould Tooling: With over 30 years of experience, our team knows what it takes to deliver high-quality tools and components.

Fast Turnaround: We offer quick quotations and rapid production timelines, with excellent capacity for both small and large-scale projects.

No MOQ: We offer flexibility with no minimum order quantity on moulded components.

ISO9001 Quality: All components are inspected in accordance with ISO9001 standards.

Industry Experience: We serve a wide range of industries, including medical, automotive, and defence, with a strong reputation for reliability and quality.

Our Tool Room Plant List

Our advanced facility is equipped with the latest technology to ensure precision and efficiency:

- Haas Super Minimill

- Haas Minimill

- Haas VF4

- TMP South Western Industries Prototrak MX3 (Manual and CNC)

- Eurospec Sparkatron SM25

- Jones & Shipman 540 Surface Grinder

- Colchester Master 2500 Lathe

- Fobco #7 Pallar Drill