FDM 3D Printing.

3D Printing for Prototyping: Fast, Effective, and Precise.

At Kent Precision, we understand the importance of quickly validating your designs before committing to full-scale production. 3D printing offers a fast, affordable, and effective solution for creating prototype parts, allowing you to test and refine your components with minimal lead time.

Free 3D Printed Samples with Your Tooling Order

When you place a mould tool order with Kent Precision, we offer 3D printed samples free of charge. This ensures that your component design is exactly as you envision it, giving you the confidence to move forward with the tooling process.

Fused Deposition Modelling (FDM) Technology

We utilize FDM (Fused Deposition Modelling) printers, which heat thermoplastic materials to build up layers, creating a fully functional prototype. Our FDM printers offer impressive speeds of up to 600mm per second and fantastic resolution, allowing us to deliver quick and accurate prints. For added strength , we use an oven to fuse the layers together, ensuring your prototype is robust enough for testing and evaluation. Our FDM printing process also provides excellent dimensional accuracy, with a tolerance of ±0.5%.

Multi-Material Printing for Versatility

We also have the capability to run up to 4 colours or materials in a single print, giving you the flexibility to create more complex components. This makes it easier to test fit and functionality before committing to a full production run. The ability to print with multiple materials ensures that you can assess how the component will behave in its intended use.

Materials that Match Injection Moulding

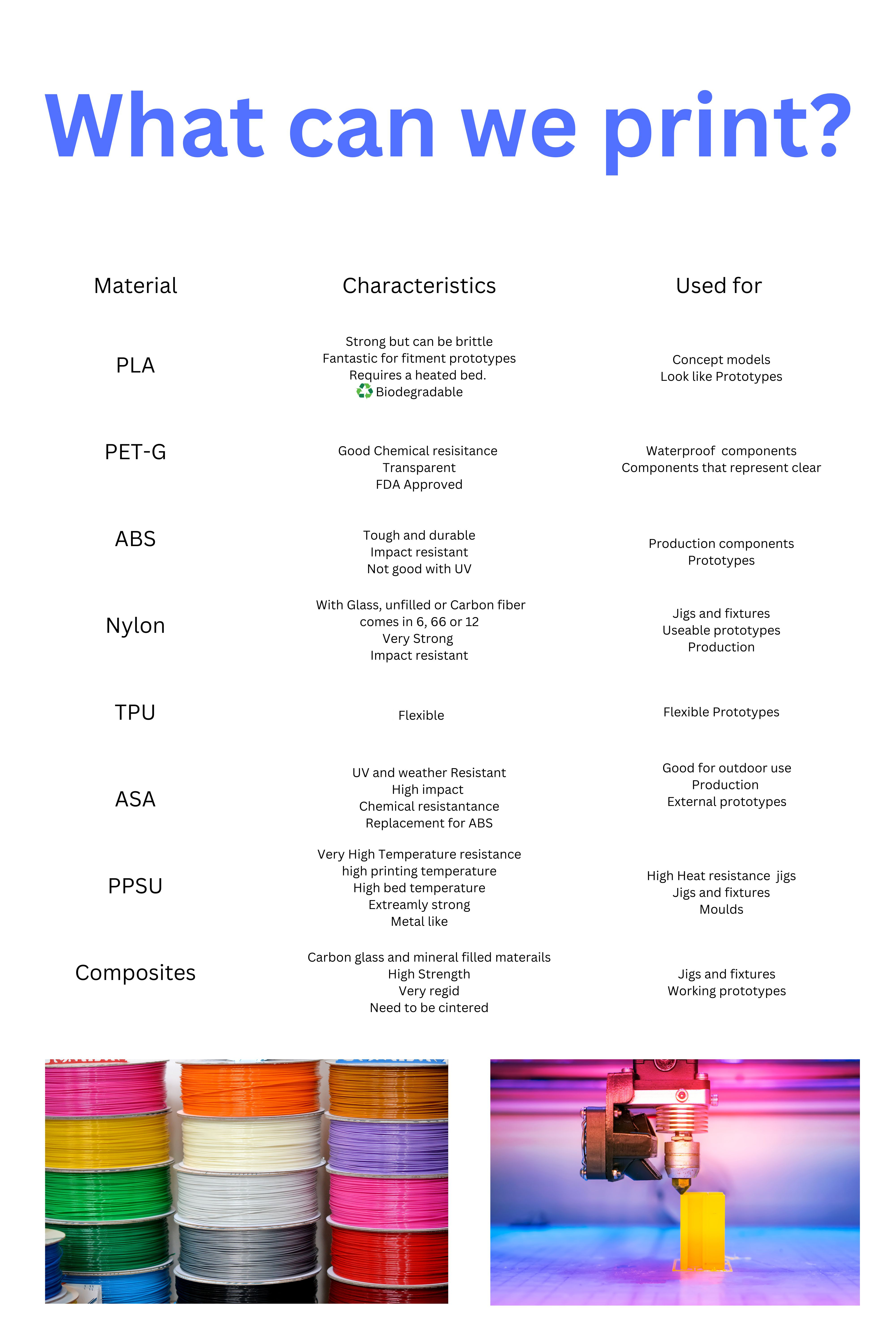

To give you the most accurate prototype, we use the same materials that are found in injection moulding. This ensures your prototype is representative of the final product in both form and function. Below is a list of the materials we offer for 3D printing:

- PET

- ABS

- ASA

- Nylon

- PPS

This approach allows you to test prototypes that are both functional and ready for real-world testing.

What Do We Need for a 3D Print?

To provide an accurate quote for your 3D print, we require a 3D drawing of your component, saved in either STL or STEP file format. If you do not have a drawing ready, we offer design and consultation services in-house to help bring your ideas to life.

Maximum Build Area

Our 3D printer has a maximum build area of 350 x 350 x 350 mm, giving us the flexibility to print a wide range of components in high resolution.

Have Questions or Specific Needs?

If you have any queries or specific 3D printing requirements, do not hesitate to contact us. We are happy to assist with any aspect of your project, from design to final print.